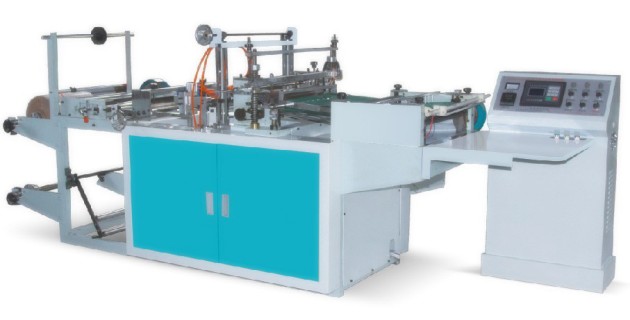

BC7 BOPP OPP PP PE Plastic Packing Bag Side Sealing Cut Forming Machine

-

BC7 BOPP OPP PP PE Plastic Packing Bag Side Sealing Cut Forming Machine

•Use & Feature:

• Work together with model BF6, Semi-finished products rolls from BF6, Do the Side Sealing Cut Forming to make finished OPP Packing Bags.

• In BOPP, PP, PE, Shrink Film materials etc. for shirts, gloves, toys etc.

• Automatic Gluing, punching, heat sealing edge. High Speed, LCD PC control.

• Step tracking feeding, Motor variable frequency speed control, Optical tracking fixed-length.

• Platen die under the pressure of high-precision, computer-controlled slice drag materials, die-cutting, waste collection once.

• Composition:

Feeder station

Die host

Induction motor with discharge

Automatic exhaust winding Model

BC7

Bag material BOPP, OPP, PP, PE, etc. Bag Length 50-800mm commonly Bag Width 70-670mm commonly Min. Bag size 25*50mm Speed 30-280 PC/Min Precision ±0.3 mm Electric-power 4.5 kw Complete weight 800 kg Voltage Customized Overall dimension L3000*W1250*H1400mm After-sales Service Provided

24h Online Engineers Service

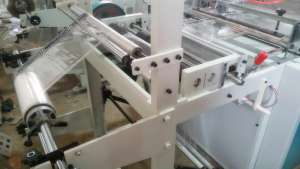

Machine Detail Photo